Carbon Steel Angle

Category:

Angle Steel

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Carbon Steel Angle

PRODUCT DETAILS

Product Description

Angle steel, commonly known as angle iron, is a long strip of steel with two sides perpendicular to each other. Angle steel can be composed of different force components according to the different needs of the structure, and can also be used as a connector between components. Widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks, cable trench supports, power piping, bus support installation, and warehouse shelves. Angle steel is carbon structural steel for construction, is a simple section of steel, mainly used for metal components and the framework of the plant. In use, it is required to have good weldability, plastic deformation performance and mechanical strength.

Product Parameters

|

Material |

A36,St37,S235J0,S235J2,St52,16mn,S355JOQ195,Q215,Q235B,Q345B,S235JR,S355JR,S355,SS440,SM400A,SM400BA572,GR50,GR60,SS540 |

|

Scope of production |

H100*100-H400*400H150*75 -H900*300 |

|

Thickness |

1-30mm |

|

Width |

15-400mm |

|

Length |

6m, 9m, 12mor according to customer requirements |

|

Technology |

Hot rolled, welded |

|

Standard |

ASTM,AISI,JIS,GB, DIN,EN |

|

Surface |

Galvanized, painted;or according to your requirements |

|

supply capacity |

2000tons/Day |

|

Business Type |

Manufacturer |

|

Certificate |

ISO, SGS,BV |

|

Application |

Widely used in building structures and engineering construction, such as room beams, ship beams, industrial furnaces, etc. |

|

loading port |

Any port in China |

|

Packaging |

Standard export packing or as your request |

|

Payment Method |

Wire transfer, spot letter of credit, Western Union, payment documents, acceptance documents, PayPal. |

|

model

|

|

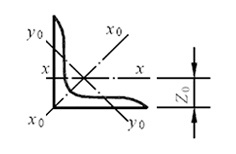

Single Angle Steel |

|

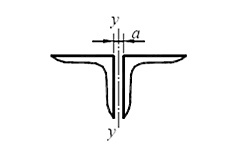

Double Angle Steel |

|||||||||||||

| Round Corners | Centroid Moment | Cross-sectional area | quality | Moment of inertia | Section modulus | Radius of gyration |

iy, 当 a 为下列数值 |

||||||||||

|

R |

Z0 |

A |

Ix |

Wxmax |

Wxmin |

ix |

ix0 |

iy0 |

6mm |

8mm |

10mm |

12mm |

14mm |

||||

|

(mm) |

(cm2) |

(kg/m) |

(cm4) |

(cm3) |

(cm) |

(cm) |

|||||||||||

|

L90×

|

6 |

10 |

24.4 |

10.64 |

8.35 |

82.77 |

33.99 |

12.61 |

2.79 |

3.51 |

1.8 |

3.91 |

3.98 |

4.05 |

4.12 |

4.2 |

|

|

7 |

24.8 |

12.3 |

9.66 |

94.83 |

38.28 |

14.54 |

2.78 |

3.5 |

1.78 |

3.93 |

4 |

4.07 |

4.14 |

4.22 |

|||

|

8 |

25.2 |

13.94 |

10.95 |

106.5 |

42.3 |

16.42 |

2.76 |

3.48 |

1.78 |

3.95 |

4.02 |

4.09 |

4.17 |

4.24 |

|||

|

10 |

25.9 |

17.17 |

13.48 |

128.6 |

49.57 |

20.07 |

2.74 |

3.45 |

1.76 |

3.98 |

4.06 |

4.13 |

4.21 |

4.28 |

|||

|

12 |

26.7 |

20.31 |

15.94 |

149.2 |

55.93 |

23.57 |

2.71 |

3.41 |

1.75 |

4.02 |

4.09 |

4.17 |

4.25 |

4.32 |

|||

|

L100× |

6 |

12 |

26.7 |

11.93 |

9.37 |

115 |

43.04 |

15.68 |

3.1 |

3.91 |

2 |

4.3 |

4.37 |

4.44 |

4.51 |

4.58 |

|

|

7 |

27.1 |

13.8 |

10.83 |

131 |

48.57 |

18.1 |

3.09 |

3.89 |

1.99 |

4.32 |

4.39 |

4.46 |

4.53 |

4.61 |

|||

|

8 |

27.6 |

15.64 |

12.28 |

148.2 |

53.78 |

20.47 |

3.08 |

3.88 |

1.98 |

4.34 |

4.41 |

4.48 |

4.55 |

4.63 |

|||

|

10 |

28.4 |

19.26 |

15.12 |

179.5 |

63.29 |

25.06 |

3.05 |

3.84 |

1.96 |

4.38 |

4.45 |

4.52 |

4.6 |

4.67 |

|||

|

12 |

29.1 |

22.8 |

17.9 |

208.9 |

71.72 |

29.47 |

3.03 |

3.81 |

1.95 |

4.41 |

4.49 |

4.56 |

4.64 |

4.71 |

|||

|

14 |

29.9 |

26.26 |

20.61 |

236.5 |

79.19 |

33.73 |

3 |

3.77 |

1.94 |

4.45 |

4.53 |

4.6 |

4.68 |

4.75 |

|||

|

16 |

30.6 |

29.63 |

23.26 |

262.5 |

85.81 |

37.82 |

2.98 |

3.74 |

1.93 |

4.49 |

4.56 |

4.64 |

4.72 |

4.8 |

|||

|

L110× |

7 |

12 |

29.6 |

15.2 |

11.93 |

177.2 |

59.78 |

22.05 |

3.41 |

4.3 |

2.2 |

4.72 |

4.79 |

4.86 |

4.94 |

5.01 |

|

|

8 |

30.1 |

17.24 |

13.53 |

199.5 |

66.36 |

24.95 |

3.4 |

4.28 |

2.19 |

4.74 |

4.81 |

4.88 |

4.96 |

5.03 |

|||

|

10 |

30.9 |

21.26 |

16.69 |

242.2 |

78.48 |

30.6 |

3.38 |

4.25 |

2.17 |

4.78 |

4.85 |

4.92 |

5 |

5.07 |

|||

|

12 |

31.6 |

25.2 |

19.78 |

282.6 |

89.34 |

36.05 |

3.35 |

4.22 |

2.15 |

4.82 |

4.89 |

4.96 |

5.04 |

5.11 |

|||

|

14 |

32.4 |

29.06 |

22.81 |

320.7 |

99.07 |

41.31 |

3.32 |

4.18 |

2.14 |

4.85 |

4.93 |

5 |

5.08 |

5.15 |

|||

|

L125× |

8 |

14 |

33.7 |

19.75 |

15.5 |

297 |

88.2 |

32.52 |

3.88 |

4.88 |

2.5 |

5.34 |

5.41 |

5.48 |

5.55 |

5.62 |

|

|

10 |

34.5 |

24.37 |

19.13 |

361.7 |

104.8 |

39.97 |

3.85 |

4.85 |

2.48 |

5.38 |

5.45 |

5.52 |

5.59 |

5.66 |

|||

|

12 |

35.3 |

28.91 |

22.7 |

423.2 |

119.9 |

47.17 |

3.83 |

4.82 |

2.46 |

5.41 |

5.48 |

5.56 |

5.63 |

5.7 |

|||

|

14 |

36.1 |

33.37 |

26.19 |

481.7 |

133.6 |

54.16 |

3.8 |

4.78 |

2.45 |

5.45 |

5.52 |

5.59 |

5.67 |

5.74 |

|||

|

L140×

|

10 |

14 |

38.2 |

27.37 |

21.49 |

514.7 |

134.6 |

50.58 |

4.34 |

5.46 |

2.78 |

5.98 |

6.05 |

6.12 |

6.2 |

6.27 |

|

|

12 |

39 |

32.51 |

25.52 |

603.7 |

154.6 |

59.8 |

4.31 |

5.43 |

2.77 |

6.02 |

6.09 |

6.16 |

6.23 |

6.31 |

|||

|

14 |

39.8 |

37.57 |

29.49 |

688.8 |

173 |

68.75 |

4.28 |

5.4 |

2.75 |

6.06 |

6.13 |

6.2 |

6.27 |

6.34 |

|||

|

16 |

40.6 |

42.54 |

33.39 |

770.2 |

189.9 |

77.46 |

4.26 |

5.36 |

2.74 |

6.09 |

6.16 |

6.23 |

6.31 |

6.38 |

|||

|

L160×

|

10 |

16 |

43.1 |

31.5 |

24.73 |

779.5 |

180.8 |

66.7 |

4.97 |

6.27 |

3.2 |

6.78 |

6.85 |

6.92 |

6.99 |

7.06 |

|

|

12 |

43.9 |

37.44 |

29.39 |

916.6 |

208.6 |

78.98 |

4.95 |

6.24 |

3.18 |

6.82 |

6.89 |

6.96 |

7.03 |

7.1 |

|||

|

14 |

44.7 |

43.3 |

33.99 |

1048 |

234.4 |

90.95 |

4.92 |

6.2 |

3.16 |

6.86 |

6.93 |

7 |

7.07 |

7.14 |

|||

|

16 |

45.5 |

49.07 |

38.52 |

1175 |

258.3 |

102.6 |

4.89 |

6.17 |

3.14 |

6.89 |

6.96 |

7.03 |

7.1 |

7.18 |

|||

|

|

12 |

16 |

48.9 |

42.24 |

33.16 |

1321 |

270 |

100.8 |

5.59 |

7.05 |

3.58 |

7.63 |

7.7 |

7.77 |

7.84 |

7.91 |

|

|

14 |

49.7 |

48.9 |

38.38 |

1514 |

304.6 |

116.3 |

5.57 |

7.02 |

3.57 |

7.67 |

7.74 |

7.81 |

7.88 |

7.95 |

|||

|

16 |

50.5 |

55.47 |

43.54 |

1701 |

336.9 |

131.4 |

5.54 |

6.98 |

3.55 |

7.7 |

7.77 |

7.84 |

7.91 |

7.98 |

|||

|

18 |

51.3 |

61.95 |

48.63 |

1881 |

367.1 |

146.1 |

5.51 |

6.94 |

3.53 |

7.73 |

7.8 |

7.87 |

7.95 |

8.02 |

|||

|

L200× |

14 |

18 |

54.6 |

54.64 |

42.89 |

2104 |

385.1 |

144.7 |

6.2 |

7.82 |

3.98 |

8.47 |

8.54 |

8.61 |

8.67 |

8.75 |

|

|

16 |

55.4 |

62.01 |

48.68 |

2366 |

427 |

163.7 |

6.18 |

7.79 |

3.96 |

8.5 |

8.57 |

8.64 |

8.71 |

8.78 |

|||

|

18 |

56.2 |

69.3 |

54.4 |

2621 |

466.5 |

182.2 |

6.15 |

7.75 |

3.94 |

8.53 |

8.6 |

8.67 |

8.75 |

8.82 |

|||

|

20 |

56.9 |

76.5 |

60.06 |

2867 |

503.6 |

200.4 |

6.12 |

7.72 |

3.93 |

8.57 |

8.64 |

8.71 |

8.78 |

8.85 |

|||

|

24 |

58.4 |

90.66 |

71.17 |

3338 |

571.5 |

235.8 |

6.07 |

7.64 |

3.9 |

8.63 |

8.71 |

8.78 |

8.85 |

8.92 |

|||

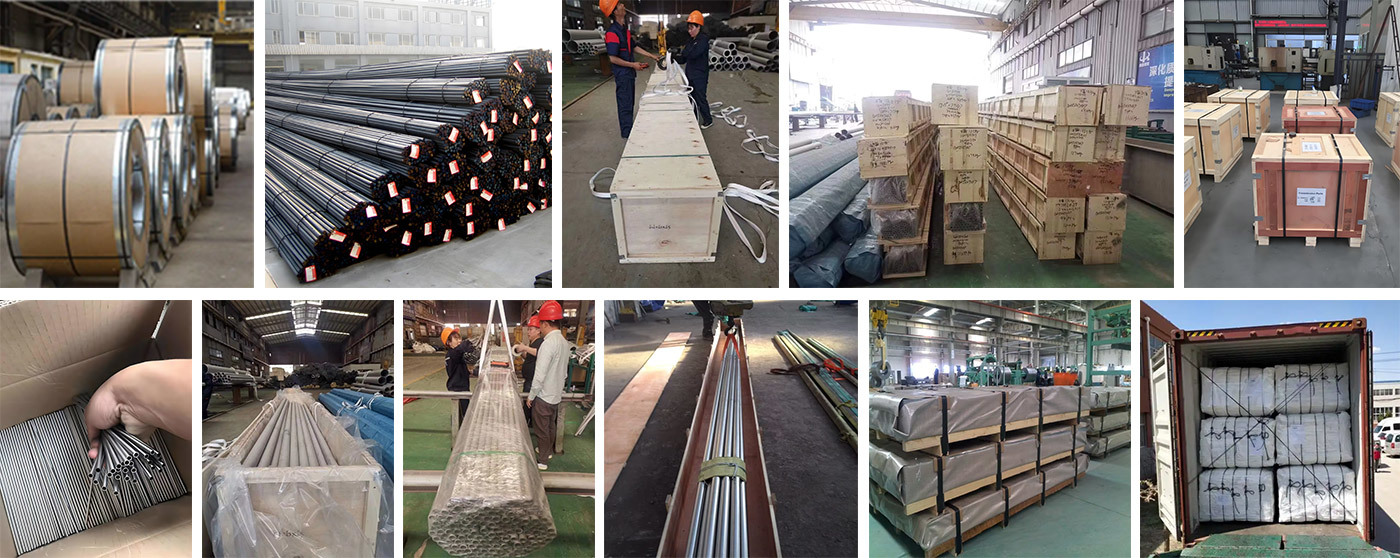

Packing And Delivery

Our advantage

experience

Many years of steel experience

01

cooperate

Good cooperative relationship

02

Source

Stable source

03

R&D

Gorgeous R & D strength

04

quality

Reliable quality assurance

05

test

Strict quality test

06

Production

CUSTOMER VISIT

HONOR

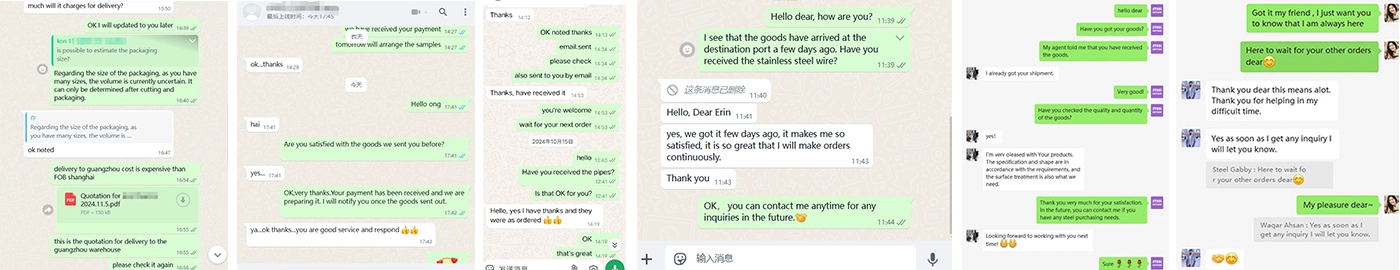

Customer communication

Partner

COMMON PROBLEM

FACTORY

APPLICATION SCENARIOS

Oil field

Aircraft manufacturing

Train manufacturing

Ship manufacturing

Power industry

Construction industry

GET A FREE QUOTE

RELATED PRODUCTS